All those scratches across sidewalls combined with rust all over can be a wake up call for you to do something about your car rims. Or, you just want to add some attitude to your car appearance? Sooner or later you will be stuck with dilemma: go wet or go dry!

Hydrographic Printing

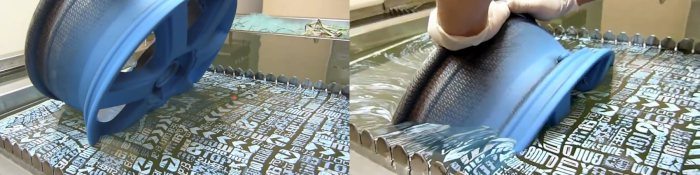

Hydrographics Printing is known by a few other names, such as; hydro dipping, immersion printing, and water transfer printing. Given those alternate names, you should already have a better idea of how Hydrographics Printing is implemented. To begin the process, a car rim is cleaned and applied an activator that loosens it’s base coat. The customized film chosen for application is than laid & floated on a vat of water. Any specialized graphics or lettering are positioned on the film at this time, and also applied an activator. This activator dissolves the film & graphics into a liquid layer that will still float on top of the water. The rim is then precisely lowered into the water. With help from the surrounding water pressure, and loosened chemical bonds from the activators, the graphics gently wrap around the rim and form a tight bond.

Benefits & Drawbacks of Hydrographic Printing

The benefits of Hydrographic Printing can be summed up in one, well-known word; Customization. Quite literally anything that can be printed from a home printer can be applied to your rims. As much as we all like to customize things, this should be a pivotal factor in your choice between Hydro Dipping VS. Powder Coat. One thing to consider as a drawback for hydrographic printing is it’s price point; on average about 100% more expensive than a Powder Coat. If you absolutely need your rims tricked out to the max, than this extra cost will be meaningless, but it’s still worth mentioning. Another thing to consider is the amount of ware & tear that rims take throughout the day. Hydrographic Printing produces a finish equal to that of car exteriors, but rims obviously sit a bit lower than exteriors.

Powder Coating

This process goes in the opposite direction; using an electrostatically applied dry powder coat paint. To begin the process, the car rim is thoroughly cleaned and grounded, giving it a negative electrical charge. The spray nozzles used for powder-coating are specially designed to apply a powerful, positive electric charge to the powder coat dust. This powerful charge actually causes the dust to accelerate towards the rim faster than it was sprayed, essentially forcing the powder to slam into the object, creating a powerful bond. This bond is later strengthened greatly with a heat cure, and the process is complete.

Benefits & Drawbacks of Powder Coating

A powder coat produces beautifully flawless finishes that are extremely durable to ware & tear. Another benefit; Powder coats can be applied MUCH thicker than liquid paints, because they don’t run or sag. A thicker coat will inevitably mean the finish will last longer, saving you plenty of hard-earned cash. It’s also a money saver because a Powder Coat is on average 50% cheaper than Hydro Dipping. One of the biggest drawbacks of Powder-Coating is the stark lack of customization options. Due to the difficulties in the process, the majority of rims can only be painted a solid color, cutting out the possibility of any carbon fiber designs or lettering. This should be considered a major drawback to powder-coating.

Decision Time

If you still can’t make up on your mind on whether to have your car rims hydro dipped, or powder coated:

just ask yourself “What am I looking for? Customization, or Durability?”

If you answered Customization, than Hydrographic Printing will surely be your choice due to it’s endless possibilities of film & vinyl overlays. Just be prepared to pay that little bit extra for the style you’re craving.

If you answered Durability, than you will surely want a Powder Coat, as the layers can be applied much thicker, and are applied with an overall stronger bonding process. Powder-coating costs considerably less, and will keep your rims fresh for longer.